Branded packaging is a key aspect of any company’s marketing strategy. A lot of time and effort goes into creating memorable designs, but what people do not think about when they see the product for sale is all those hours that went in beforehand; designing it, printing it out on high-quality paper stock with vibrant colors, so your logo pops off the shelf at every customer who walks by.

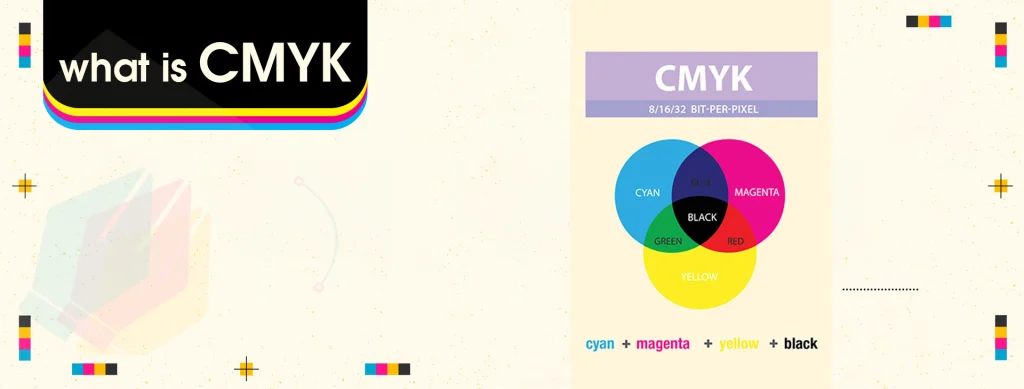

The CMYK printing process is a widely utilized technique for digital and offsets print. CMYK stands for Cyan, Magenta, Yellow, and Black.

These four colors are the basis of all colors printing in the world. It is important to know how these colors work together when designing a logo or image that will be printed on packaging products.

In this blog post, we will explore the fascinating industry of color printing through understanding CMYK.

What is CMYK Color Model?

The CMYK is abbreviated for Cyan, Magenta, Yellow, and Key: these are the colors used in the printing process.

Ink is added to a plate with raised areas that hold onto it until pressed against paper or other printable material such as cloth or leather – this creates your printed images. The black color called ‘Key’ actually refers back to its roots meaning Black because it is needed primarily when creating an outcome-orientated design by determining what will be dark colors on white light spaces.

While cyan and yellow create green upon being overlaid one another, which can then create many variations of different tones depending on how they are mixed together.

What Does Key Mean in CMYK?

Key is a word that means black, and it may have originated from the process of printing. When you print, there are four colors – cyan, yellow, magenta, and Key (Black).

The order matters because when they are put together in layers on paper or something else printed with ink colorings, only one layer can be shown at once, so if one does not align to another well, then this leads to what we call “banding,” which also looks like an icky rainbow effect.

This being said, Key could mean any color plate really just depending on how things go down during production.

How Does CMYK Color Printing Works?

The process of CMYK colors is both simple and complex. First, it starts with the desired design or color that needs to be created in a print medium. From there, they are mixed together on four different plates: cyan (C), magenta (M), yellow(Y), Black (K).

The subtractive synthesis technique then takes over; this is where primary colors mix together, just like paint does when you are painting something from scratch. They create more vivid colors than what had initially been imagined for your project.

This printing method uses ink instead of paints which makes each layer blend into one another slightly differently so as we absorb less light through your eyes while viewing the subtle gradients between tones-colors rather than being fixated.

When you print, the colors are determined by how light is reflected. The intensity of these reflections determines whether or not a color will be dark or bright on your paper. For example, if there is only one color in ink and it is at its highest level, that means black – but when all four colors are added to an image, then white shows up instead.

How Do CMYK Color Model Codes Work?

Making design and print files in CMYK can seem rather confusing, but luckily it is a lot simpler than you may think. We only have control over the intensity of each color from 0 to 100, with “0” being for pure Cyan ink and every other number representing an increasing level of that specific color’s pigment strength. So, if we want one shade or another more intense version, simply use a different code.

Color is made of three primary colors. The only exception to this rule is black, where the purest form of Black would be C100, M100, Y100, and K00 because the print gets darker as you increase color intensity.

CMYK Packaging

Printing today has been given a makeover with the rise of new and exciting colors. The CMYK color system is making it easier for printers to create custom packaging that suits their needs using offset printing, flexo printing, or digital methods like RGB.

These types of print jobs are made possible by these newer ink blends, which have more variations than just red and blue primary colors, such as yellow-green pigments being used in any kind of light green tints you can imagine.

When producing packaging for custom printing jobs, it is important to note that not all colors are possible with the CMYK system. To see if you would be happy with your outcome, you should convert your RGB images into one of the 4-color options available in this system and check them out on a printer before proceeding.

The Resolution of CMYK

The RGB color process is ineffective for printing purposes because inks of three colors (red, green, blue) would have to be mixed to get white. This can cause a problem when it comes time for recycling; the ink used by printers is no longer pure and therefore cannot always go into with other recycled papers or plastics that are not meant for use as paper but still requires water-based coloring agents.

To create a full spectrum of colors, the CMY (Cyan Magenta Yellow) system was created. Blue can be made by combining cyan and magenta together. Mixing yellow with blue yields green, while mixing red with yellow gives you orange.

What you may have already known is that black ink has always been a part of four-color printing. However, printers once had to mix cyan, magenta, and yellow inks for the purposes of creating blacks as well.

Fortunately, this was not needed anymore because it was more efficient just to use one color: Black! This discovery led to CMYK (Cyan, Magenta Yellow Key), which can be considered subtractive since they need fewer common combinations such as red & blue or green & purple until reaching white.

The Usage of CMYK

The CMYK process is the most common way that home printers work. However, it’s also used by a lot of printing companies to print flyers and posters for other projects.

The low cost has made this color process popular with many manufacturers who produce printed packaging materials because they can provide lower quantities at an affordable price when using CMYK colorspace instead of Pantone or spot inks which are limited supply and often more expensive per unit than inkjet cartridges.

Can you imagine how frustrating it would be if the ink of your dreams didn’t stick to metal, plastic, or any material other than paper? That is what happens with CMYK colors.

Not only does this make printing difficult for people who want to print on different surfaces such as glass and wood, but it also makes putting together a design more complicated because not all elements will look good in every color format.

The Color Mixture of CMYK

Mixing CMYK colors requires a more complex process than just dipping the brush into the paint and wiping it across sheets of paper. When printing, these four colors are actually printed in very small dots that overlap with each other to create different tones or shades within one color.

When printing occurs, the colors do not really get mixed but printed as tiny cyan or magenta dots on top of yellow ones, for example – so our eyes see them separately even if we wanted one color in an area with another color because there’s this layer between them that makes all those little spots look different from what they would’ve been without any layers at all.

Positive Aspects of CMYK

CMYK can be used to be printed with water-based inks and plastisol. It is not rustic and feels soft to the hand. It gives a good texture to the packaging and gives great finishing. Moreover, it is recommended to print it wet on wet.

What Important Things to Consider?

There are a lot of things to take into consideration when it comes time to print your design. If you are printing on fabric, be sure that all the colors will show up correctly because some dye-based inks cannot reproduce certain hues.

Additionally, suppose you want vibrant reds or other rare shades printed on paper and offset through various screens for different color options (optical brighteners). In that case, they will need some extra oomph from a bump screen before getting sent off for reproduction by an inkjet printer.

The Final Takeaway

The CMYK printing option is great for printing packages. It takes your packaging to the next level and provides every color that you can imagine. Read the above guide about CMYK and get all the information about the printing process before proceeding with your packaging solution.