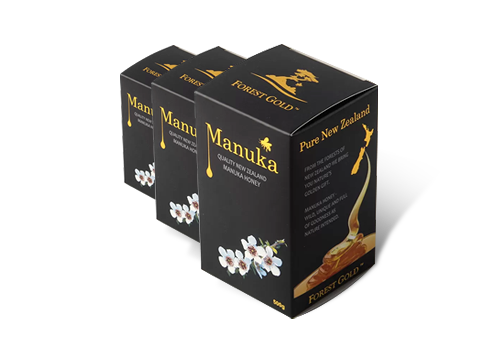

Foil Stamping is a process that has been used for decades to make packaging more appealing and eye-catching. It is vital in the food industry and found in other markets such as cosmetics, electronics, and even clothing. There are many different types of foil stamping too.

We will learn what is foil stamping, its applications, and everything you need to know about this popular trend.

What is Foil Printing?

Foil stamping is a process that uses pressure and heat to apply an aluminum or gold-colored sheet of metal onto paper, plastic, fabric, and other items. This has been done on the product packaging for decades.

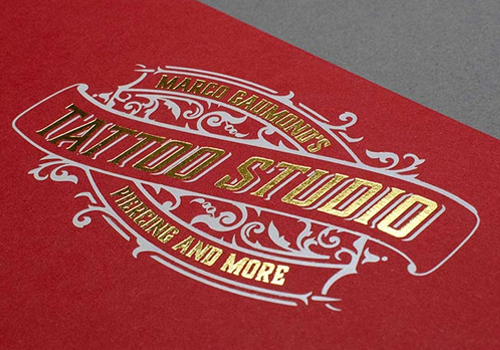

It is a great way to get the best of both worlds. With this technique, you can create holographic textures with metallic finishes or matte and glossy effects that are like no other.

Stamping printing is a procedure that prints without using any ink. When executed properly, this technique can be used to print products with dark surfaces without being affected by the color or texture of the medium, like pad printing and silk-screening techniques.

It is a fairly old process used to create many types of products. Some examples would be holiday cards, baby announcements, or scratch-off foil for lottery tickets.

By using this technique and tiny metal leaves that are put into the design in advance, you can make anything from wedding invitation ideas to presentation folders more interesting.

The Foil Stamping Process

Foil-stamped printing is a true art form. It utilizes pressure, heat, and metal foils to create dazzling designs in the shape of letters, words, or graphics with limitless colors at an affordable price.

The hot stamping process starts by using a heated metal tool to transfer ink from the “hot” end of the machine onto paper. The heat is necessary for transferring images and creating that raised effect on surfaces like cotton, linen, or silk.

This type of method, also known as dry foil stamping, is a method that does not include using any sort of ink for printing. Instead, dies and carved metallic plates are used in this process to create unique pieces.

There are typically five layers in the foil, each with its specific job: metal layers, lacquer layers, image layers, a release layer, and a polyester carrier layer. Additionally, there is an outer adhesive layer

It is a process that applies heat and pressure to the foil, which in turn presses against the medium being supported by either of two plates.

The machine hot foils an adhesive layer that melts and attaches to the medium when a pressure roller heats it. The brass dies used in the hot foil stamper are usually hand-etched or engraved through other methods.

A hot foil stamper is a machine that can either be connected to another device or work independently. This tool uses heat and pressure from the rollers on top of the hot stamping printing plate. These help to produce beautiful images with shiny foils placed behind them for an exciting touch.

The Applications of Foil Stamping

The ancient art of hot foiling has been used to decorate and protect product boxes for centuries. These days, it is not only a decoration but also an anti-counterfeiting measure that ensures your product’s authenticity.

Foil stamping is a way to create unique, one-of-a-kind designs that make packaging items and other products stand out. These were used in the wine industry and on currency notes, but they also have applications for greeting cards, wedding invitations, book covers, and paper stock.

It is a quick way to add luxurious effects and eye-catching factors. For example, stickers can be stamped with metallic ink for an elegant look that will last long after peeling the sticker off its surface.

2 Different Types of Foil Stamping

We will now shed light on 2 different types of hot foiling, which are as follows:

i) Traditional Foil Stamping

To make a foil stamp, the design to be stamped is engraved or etched into an aluminum plate known as a die. The machine’s mechanics create a unique design in foil. Which is then transferred onto objects using heat and pressure.

Separate metal dies need to be prepared for each colored design if more than one is required. The die needs to be applied in order, starting with the first color and following up through all of them when necessary until completion.

For the perfect embellishment to any embossed design, a special effects foil die needs to be prepared. This roller leaves behind an impression that mimics three-dimensional textures on the medium’s surface. It can give your project just what it is missing.

ii) Digital Foil Stamping

A digital hot foiling machine is an advanced type of printer that heats foil to a high temperature. It then presses the foil onto the surface in one layer. This process creates designs with deeper colors than traditional printing methods are capable of producing.

A digital hot foiling machine is an advanced type of printer that heats foil to a high temperature. It then presses the foil onto the surface in one layer. This process creates designs with deeper colors than traditional printing methods are capable of producing.

This process is extremely popular with graphic designers because it gives them the freedom to create any design they can think of and use in their artwork.

It is a fast and easy method of printing with many benefits. This can be used to print one or more colors, which saves money on ink supplies needed for other types of prints, such as offset lithography.

In Conclusion

There are many different types of foil stamping, and it is an important technique in custom packaging. It can be used for other products too, such as clothing and electronics.

Foil stamping is very popular due to the eye-catching appeal that this process brings out in a product. Brands use it because they know consumers will gravitate towards these new additions to their collections or packaging lineups. Consumers are particularly drawn to shiny, shimmery, metallic colors.

READ MORE:

Embossed vs Debossed for Packaging – Which One to Choose?

Matte vs Gloss Lamination – Which Is Right for Packaging?

Spot Color vs CMYK for Packaging